Energy consumption

On an average, Indian mills use 50 giga joules of energy

to make one tonne of paper. Ballarpur Industries Ltd’s Chaudwar unit’s energy

consumption is the worst imaginable |

|

Chemical use

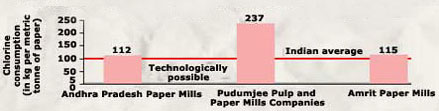

The world moves on to chlorine-free bleaching, but Indian

mills are far from following suit. Average chlorine consumption in Indian stands at 100 kg

per tonne of paper |

|

Recommendations to the sector

The objective of GRP was not only to rate the environmental performance but also recommend

ways to improve it. The recommendations given to the pulp and paper sector were as

follows:

1. Inputs

Sourcing of wood: Although the 1988

National Forest Policy does not allow sourcing of raw materials from government forests,

the government has not made any plan to work with the pulp and paper industry to promote

farm forestry. A good farm forestry programme can help to bring a large portion of

degraded lands owned by poor farmers under a remunerative green cover. But as such a

programme would have both national and commercial objectives, a part of the cost should be

borne by the state. Currently, the government continues to supply fibre resources from

government forests, which kills the farm forestry market due to the substantial difference

in wood prices. Despite the lack of a good policy framework to promote farm forestry,

there are several pulp and paper companies (such as Andhra Pradesh Pulp and Paper mills,

ITC Bhadrachalam Paperboards Ltd., etc.), which are trying to fulfil at least a part of

their needs from farmers. Both government agencies and private companies should learn from

their experiences. Sourcing of wood: Although the 1988

National Forest Policy does not allow sourcing of raw materials from government forests,

the government has not made any plan to work with the pulp and paper industry to promote

farm forestry. A good farm forestry programme can help to bring a large portion of

degraded lands owned by poor farmers under a remunerative green cover. But as such a

programme would have both national and commercial objectives, a part of the cost should be

borne by the state. Currently, the government continues to supply fibre resources from

government forests, which kills the farm forestry market due to the substantial difference

in wood prices. Despite the lack of a good policy framework to promote farm forestry,

there are several pulp and paper companies (such as Andhra Pradesh Pulp and Paper mills,

ITC Bhadrachalam Paperboards Ltd., etc.), which are trying to fulfil at least a part of

their needs from farmers. Both government agencies and private companies should learn from

their experiences.

|

| The paper sector rating clearly

showed the importance of proper natural resource pricing for better resource efficiency |

|

|

Wastepaper

recycling: Even though India does recycle her resources to a considerable extent, yet

her performance in terms of wastepaper collection and recycling for paper-making purposes

remains extremely poor by world standards. As a result, India today is importing

wastepaper. The government and paper companies should together develop a major wastepaper

collection and recycling programme. Wastepaper

recycling: Even though India does recycle her resources to a considerable extent, yet

her performance in terms of wastepaper collection and recycling for paper-making purposes

remains extremely poor by world standards. As a result, India today is importing

wastepaper. The government and paper companies should together develop a major wastepaper

collection and recycling programme.

Long-term

Policy for Fibre Supply: The government and the pulp and paper industry must develop a

longterm vision and programme for sustainable and environment-friendly fibre supply for

the country. Plantations and development of fibrous resources are long-term investments

and both the government and industry must realise that these investments will neither be

made nor sustained unless there is longterm support for them in the form of appropriate

market conditions and fiscal incentives. As of now, government policies have been erratic

and changing from time to time. Long-term

Policy for Fibre Supply: The government and the pulp and paper industry must develop a

longterm vision and programme for sustainable and environment-friendly fibre supply for

the country. Plantations and development of fibrous resources are long-term investments

and both the government and industry must realise that these investments will neither be

made nor sustained unless there is longterm support for them in the form of appropriate

market conditions and fiscal incentives. As of now, government policies have been erratic

and changing from time to time.

Pricing of

Water: Freshwater consumption by Indian pulp and paper mills is high and conservation

should be encouraged through a rational pricing structure. Consumption beyond an

acceptable level should be priced at a progressively higher rate. Pricing of

Water: Freshwater consumption by Indian pulp and paper mills is high and conservation

should be encouraged through a rational pricing structure. Consumption beyond an

acceptable level should be priced at a progressively higher rate.

Sourcing of

Water: Most pulp and paper mills have a large amount of land and they should be

capturing and using their rainwater endowment. It is recommended that mills should think

in terms of sourcing at least a part of their water requirements through rainwater

harvesting. A calculation made for Sinar Mas showed that nearly 50 per cent of the

company’s current water consumption could be met through its rainwater endowment.

Water recycling should also be encouraged to the maximum extent possible. Sourcing of

Water: Most pulp and paper mills have a large amount of land and they should be

capturing and using their rainwater endowment. It is recommended that mills should think

in terms of sourcing at least a part of their water requirements through rainwater

harvesting. A calculation made for Sinar Mas showed that nearly 50 per cent of the

company’s current water consumption could be met through its rainwater endowment.

Water recycling should also be encouraged to the maximum extent possible.

Sourcing of

Energy: Erratic and inadequate electricity supply is forcing mills to move

towards smaller electricity generating systems which use furnace oils, low sulphur high

stock (LSHS) fuel oil and other heavier fractions which are not only subsidised but also

very polluting. The government must make efforts to improve its electricity supply and

work with the pulp and paper industry to use environmentfriendly energy sources as much as

possible. Sourcing of

Energy: Erratic and inadequate electricity supply is forcing mills to move

towards smaller electricity generating systems which use furnace oils, low sulphur high

stock (LSHS) fuel oil and other heavier fractions which are not only subsidised but also

very polluting. The government must make efforts to improve its electricity supply and

work with the pulp and paper industry to use environmentfriendly energy sources as much as

possible.

2. Process and technology

Technological upgradation: The pulp and paper industry today

works with a technology that is way below international standards, which also results in

inefficient resource utilisation and ultimately low environmental performance. The current

Indian technology is the same as that used in the Scandinavian countries in the 1950s and

1960s. The Indian pulp and paper sector should invest in technology upgradation and the

government should come up with a package of measures to facilitate this upgradation. Technological upgradation: The pulp and paper industry today

works with a technology that is way below international standards, which also results in

inefficient resource utilisation and ultimately low environmental performance. The current

Indian technology is the same as that used in the Scandinavian countries in the 1950s and

1960s. The Indian pulp and paper sector should invest in technology upgradation and the

government should come up with a package of measures to facilitate this upgradation.

|

| During the paper sector

rating, the project found that the very debate on the use of chlorine free bleaching has

passed largely unnoticed in India |

|

|

Without improvement in technology, management

practices and government regulations, environmental performance of the pulp and paper

sector will remain low.

Use

of chlorine: The global debate on the use of Elemental Chlorine Free (ECF) bleaching

and Total Chlorine Free (TCF) bleaching, to reduce environmental pollution, has passed

largely unnoticed in India. It is recommended that those mills which have poor technology

should not get into manufacturing high brightness paper so that they can get away with the

most polluting aspect of paper-making, that is, bleaching with elemental chlorine. Only

firms with good process technology and end-of-pipe treatment should make bleached paper.

Government agencies and NGOs should also launch an awareness programme to promote the use

of unbleached paper. A national discussion should be initiated by the Use

of chlorine: The global debate on the use of Elemental Chlorine Free (ECF) bleaching

and Total Chlorine Free (TCF) bleaching, to reduce environmental pollution, has passed

largely unnoticed in India. It is recommended that those mills which have poor technology

should not get into manufacturing high brightness paper so that they can get away with the

most polluting aspect of paper-making, that is, bleaching with elemental chlorine. Only

firms with good process technology and end-of-pipe treatment should make bleached paper.

Government agencies and NGOs should also launch an awareness programme to promote the use

of unbleached paper. A national discussion should be initiated by the

Central Pollution Control Board on the need to ban

the use of elemental chlorine and a statutory warning, which says that this paper is made

using chlorine.

Use of agro-residues: CSE’s Green

Rating Project has rated the large-scale pulp and paper sector which has a better

environmental performance than the sector which has been left out, that is, the small,

agro-residue-based mills. India has consciously promoted agroresidue-based mills but there

is a need to think afresh on how this sector should be developed to meet the

country’s pulp and paper needs as it also helps to generate rural employment and

increase rural incomes. In order to reduce the environmental impact of these mills, it is

recommended that any new mill with a production capacity of 40 tonnes per day with a

chemical pulping process using agro-residues or wood should not be allowed to operate

without a chemical recovery system. As the pulping process is more environmentally harmful

than the paper-making process, large-scale mother pulp mills with a chemical recovery

system should be set up to meet the pulp needs of smaller paper mills. A good research and

development facility should be developed to fulfil the needs of agro-based firms by

developing environment-friendly technologies for processes like chemical recovery systems. Use of agro-residues: CSE’s Green

Rating Project has rated the large-scale pulp and paper sector which has a better

environmental performance than the sector which has been left out, that is, the small,

agro-residue-based mills. India has consciously promoted agroresidue-based mills but there

is a need to think afresh on how this sector should be developed to meet the

country’s pulp and paper needs as it also helps to generate rural employment and

increase rural incomes. In order to reduce the environmental impact of these mills, it is

recommended that any new mill with a production capacity of 40 tonnes per day with a

chemical pulping process using agro-residues or wood should not be allowed to operate

without a chemical recovery system. As the pulping process is more environmentally harmful

than the paper-making process, large-scale mother pulp mills with a chemical recovery

system should be set up to meet the pulp needs of smaller paper mills. A good research and

development facility should be developed to fulfil the needs of agro-based firms by

developing environment-friendly technologies for processes like chemical recovery systems.

3. Wastes and pollution

Wastewater

discharge standards: Wastewater discharge standards should not differentiate between

wastewater discharged in surface waters and wastewater discharged on land. There is a

substantial difference between the two standards. For example, the standard for

biochemical oxygen demand (BOD) of wastewater to be discharged in water bodies is 30

mg/litre whereas it is 100 mg/litre for discharge on land. During the Green Rating

exercise, it was found that most of mills which discharge their wastewaters on land also

discharge their wastewaters into water bodies, especially during the rainy season. During

this season, the land is saturated with rainwater and does not require wastewater for

irrigation. Moreover, there is heavy runoff from farms to water bodies during this period. Wastewater

discharge standards: Wastewater discharge standards should not differentiate between

wastewater discharged in surface waters and wastewater discharged on land. There is a

substantial difference between the two standards. For example, the standard for

biochemical oxygen demand (BOD) of wastewater to be discharged in water bodies is 30

mg/litre whereas it is 100 mg/litre for discharge on land. During the Green Rating

exercise, it was found that most of mills which discharge their wastewaters on land also

discharge their wastewaters into water bodies, especially during the rainy season. During

this season, the land is saturated with rainwater and does not require wastewater for

irrigation. Moreover, there is heavy runoff from farms to water bodies during this period.

Avoiding

land contamination: It is important that all mills which discharge their wastewater on

land even with the discharge standards for surface water should monitor the soil

characteristics and quality of crops grown on the land irrigated by the effluent. A few

studies have shown that though the productivity of the land goes up initially because of

the availability of plant nutrients in the effluent, the land becomes unproductive after

five to ten years due to increased soil salinity. Since soil contamination is difficult to

reverse, it is important to assess the impact of effluent used for irrigation before

allowing any mill to discharge its effluent in this manner. Thus, before allowing any mill

to do so, it could be asked to first discharge them on its own land so that the results

can be studied over a fairly long time frame. Avoiding

land contamination: It is important that all mills which discharge their wastewater on

land even with the discharge standards for surface water should monitor the soil

characteristics and quality of crops grown on the land irrigated by the effluent. A few

studies have shown that though the productivity of the land goes up initially because of

the availability of plant nutrients in the effluent, the land becomes unproductive after

five to ten years due to increased soil salinity. Since soil contamination is difficult to

reverse, it is important to assess the impact of effluent used for irrigation before

allowing any mill to discharge its effluent in this manner. Thus, before allowing any mill

to do so, it could be asked to first discharge them on its own land so that the results

can be studied over a fairly long time frame.

Improving

discharge standards: The Central Pollution Control Board should consider the

development of site-specific load-based standards rather than concentration-based

standards. Improving

discharge standards: The Central Pollution Control Board should consider the

development of site-specific load-based standards rather than concentration-based

standards.

Fiscal Incentives: The Green Rating

Project found that hardly any company or manager was making an attempt to improve

environmental performance beyond the regulatory standards set by the government. There is

no motivation to go beyond the standards. All over the world, if there are only regulatory

standards, companies see the meeting of these standards as the maximum effort they need to

make to meet their environmental responsibilities. But if fiscal incentives are provided

to companies which go beyond these standards, then meeting the standards becomes the

minimum effort that is made by a company to meet its environmental responsibilities. The

government should consider such fiscal incentives for the pulp and paper sector. Fiscal Incentives: The Green Rating

Project found that hardly any company or manager was making an attempt to improve

environmental performance beyond the regulatory standards set by the government. There is

no motivation to go beyond the standards. All over the world, if there are only regulatory

standards, companies see the meeting of these standards as the maximum effort they need to

make to meet their environmental responsibilities. But if fiscal incentives are provided

to companies which go beyond these standards, then meeting the standards becomes the

minimum effort that is made by a company to meet its environmental responsibilities. The

government should consider such fiscal incentives for the pulp and paper sector.

Deemed

Consent: There is a loophole in the pollution control system in the way consent is

given by pollution control boards. If the pollution control board does not give consent

within four months of application, then the company can take it as ‘deemed

consent’. Many pulp and paper companies are today operating on ‘deemed

consent’. The Central government should institute sanctions against state pollution

control boards, which do not take a decision to give or refuse consent within the

specified period. Deemed

Consent: There is a loophole in the pollution control system in the way consent is

given by pollution control boards. If the pollution control board does not give consent

within four months of application, then the company can take it as ‘deemed

consent’. Many pulp and paper companies are today operating on ‘deemed

consent’. The Central government should institute sanctions against state pollution

control boards, which do not take a decision to give or refuse consent within the

specified period.

Staff

Training: Pulp and paper mills should undertake staff training programmes to improve

the understanding of environmental management, which is currently poor. Even top managers

of these mills should undergo such training, which includes process management policies,

sourcing of sustainable and environmentfriendly raw materials, and waste disposal

policies. Staff

Training: Pulp and paper mills should undertake staff training programmes to improve

the understanding of environmental management, which is currently poor. Even top managers

of these mills should undergo such training, which includes process management policies,

sourcing of sustainable and environmentfriendly raw materials, and waste disposal

policies.

Standardisation of information

disclosure: Annual report contain a substantial amount of information but either

the government or the industrial associations should prepare a standardised format for the

pulp and paper sector. Companies with several mills should provide resource and energy

consumption and production figures separately for different mills. Standardisation of information

disclosure: Annual report contain a substantial amount of information but either

the government or the industrial associations should prepare a standardised format for the

pulp and paper sector. Companies with several mills should provide resource and energy

consumption and production figures separately for different mills.

Community

Relations: Relations between pulp and paper companies and local communities appear to

be quite strained in many cases. Companies should not only improve their environmental

performance but also work with the local communities in their efforts to improve their

environmental performance. Companies should report in their Annual Reports, the efforts

they have made to disclose information to local communities, increase their understanding

of environmental issues, involve them in the management of wastewater or supply of inputs,

etc. A certain amount of money should be set aside for community relations. Community

Relations: Relations between pulp and paper companies and local communities appear to

be quite strained in many cases. Companies should not only improve their environmental

performance but also work with the local communities in their efforts to improve their

environmental performance. Companies should report in their Annual Reports, the efforts

they have made to disclose information to local communities, increase their understanding

of environmental issues, involve them in the management of wastewater or supply of inputs,

etc. A certain amount of money should be set aside for community relations.

With these recommendations, the project had finished

the rating of pulp and paper sector. |

![]()